Stamping Die Design

Summit Tool Design| 13136 Thunderhead Falls Lane | Rapid City, SD| 57702-8528 | Tel: 815-399-5460

Design Communication

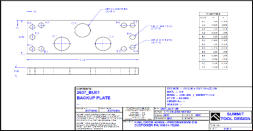

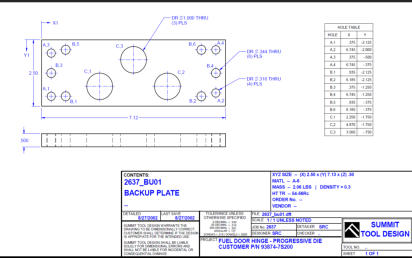

Even though the machine trades are working hard to implement paperless manufacturing, there is still a real need to have paper drawings, or at least a drawing in digital format that supports the CNC processes. Summit Tool Design delivers a complete package of 3D Models, Plan and Section Views, Bill of Material and 2D Detail Drawings.Forming Simulation

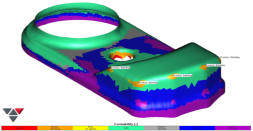

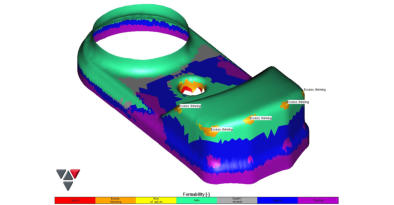

Forming simulation and virtual die tryout with AutoForm Software indentifies forming problems like splits, cracks and wrinkles. • Improves reliability. • Reduces the number of die tryouts and tryout time. • Results in a higher quality part and tool design. • Builds confidence in the designed process. • Production downtime and reject rates are substantially reduced.

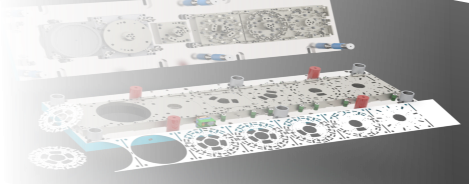

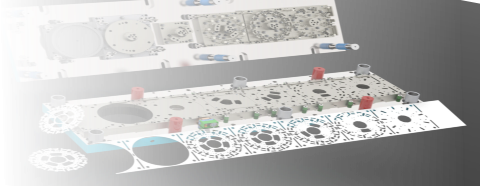

Benefits of 3D Die Design

Virtual 3D die assemblies help with: • Solving complex design problems. • Interference checking. • Checking for feed path obstructions. • Improved quality and reliability. • Ensuring accuracy for“right the first time” design. • Better design visualization interpretation. • CAD geometry ready for CNC programming.

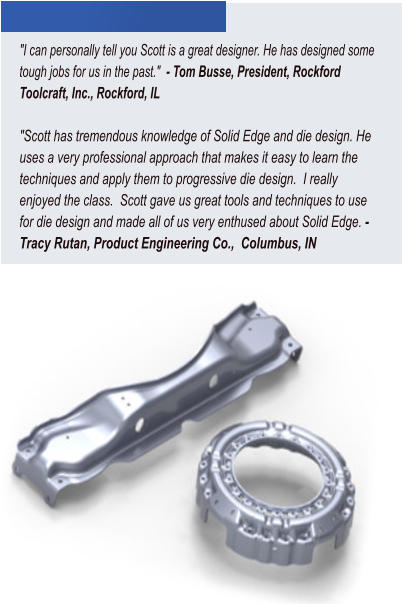

What Others Are Saying

Summit Tool Design specializes in Progressive Dies

Summit Tool Design offers your company experienced and innovative tool design services to meet the complex requirements of your sheet metal stamping dies and other tooling projects. We use Solid Edge and other advanced software tools to craft our tool designs. With a complete 3D model of the Stamping Die Assembly and Process, it easier to optimize a die design and analyze the potential problems before the design is released to the shop for build. It is very time-consuming and costly to recover from an error in the shop. With the enhanced capabilities that 3D design offers, it is easier to make sure those errors don't happen.State-of-the-art design with premium quality service in a timely fashion

Summit Tool Design has experience with a broad spectrum of products across a range of industries including automotive & heavy truck, agriculture, home appliance, hardware, furniture, electrical, electronics, medical and power tool.

Tool Design

Stamping Die Design

Summit Tool Design| 13136 Thunderhead Falls Lane

Rapid City, SD| 57702-8528 | Tel: 815-399-5460

Design Communication

Even though the machine trades are working hard to implement paperless manufacturing, there is still a real need to have paper drawings, or at least a drawing in digital format that supports the CNC processes. Summit Tool Design delivers a complete package of 3D Models, Plan and Section Views, Bill of Material and 2D Detail Drawings.

Forming Simulation

Forming simulation and virtual die tryout with AutoForm Software indentifies forming problems like splits, cracks and wrinkles. • Improves reliability. • Reduces the number of die tryouts and tryout time. • Results in a higher quality part and tool design. • Builds confidence in the designed process. • Production downtime and reject rates are reduced.

Benefits of 3D Die Design

Virtual 3D die assemblies help with: • Solving complex design problems. • Interference checking. • Checking for feed path obstructions. • Improved quality and reliability. • Ensuring accuracy for“right the first time” design. • Better design visualization interpretation. • CAD geometry ready for CNC programming.

What Others Are Saying

Summit Tool Design specializes

in Progressive Dies

Summit Tool Design offers your company experienced and innovative tool design services to meet the complex requirements of your sheet metal stamping dies and other tooling projects. We use Solid Edge and other advanced software tools to craft our tool designs. With a complete 3D model of the Stamping Die Assembly and Process, it easier to optimize a die design and analyze the potential problems before the design is released to the shop for build. It is very time- consuming and costly to recover from an error in the shop. With the enhanced capabilities that 3D design offers, it is easier to make sure those errors don't happen.State-of-the-art design with

premium quality service in a

timely fashion

Summit Tool Design has experience with a broad spectrum of products across a range of industries including automotive & heavy truck, agriculture, home appliance, hardware, furniture, electrical, electronics, medical and power tool.Tool Design